Topology optimization and 3D printing of multimaterial magnetic actuators and displays

Publication

Science Advances

Authors

Subramanian Sundaram, Melina Skouras, David S. Kim, Louise van den Heuvel, Wojciech Matusik

Abstract

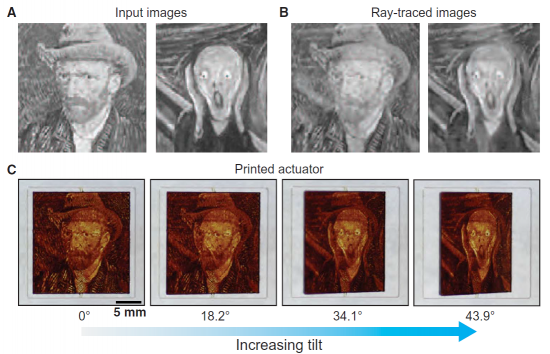

Upcoming actuation systems will be required to performmultiple tightly coupled functions analogous to their natural counterparts; e.g., the ability to control displacements and high-resolution appearance simultaneously is necessary for mimicking the camouflage seen in cuttlefish. Creating integrated actuation systems is challenging owing to the combined complexity of generating high-dimensional designs and developing multifunctional materials and their associated fabrication processes. Here, we present a complete toolkit consisting of multiobjective topology optimization (for design synthesis) and multimaterial drop-on-demand three-dimensional printing for fabricating complex actuators (>106 design dimensions). The actuators consist of soft and rigid polymers and a magnetic nanoparticle/polymer composite that responds to a magnetic field. The topology optimizer assigns materials for individual voxels (volume elements) while simultaneously optimizing for physical deflection and high-resolution appearance. Unifying a topology optimization-based design strategy with a multimaterial fabrication process enables the creation of complex actuators and provides a promising route toward automated, goal-driven fabrication.